|

|

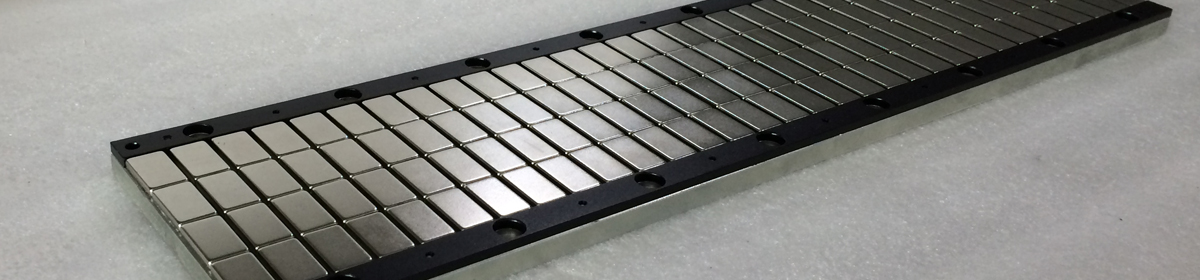

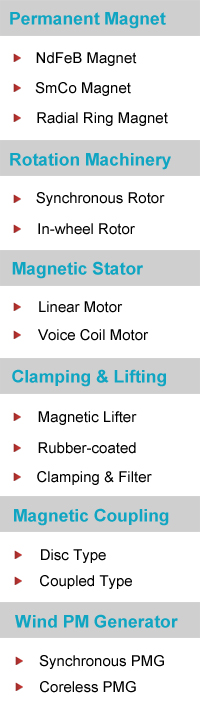

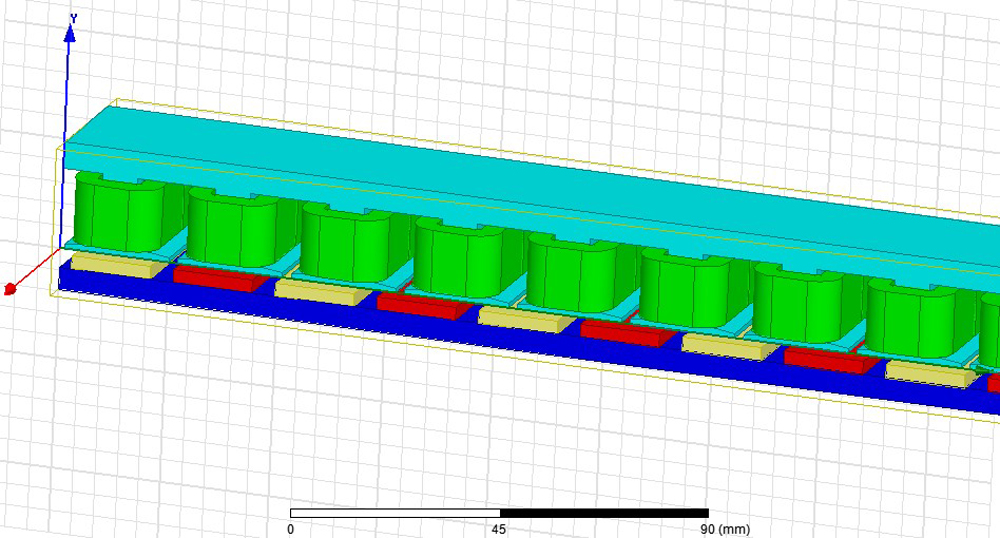

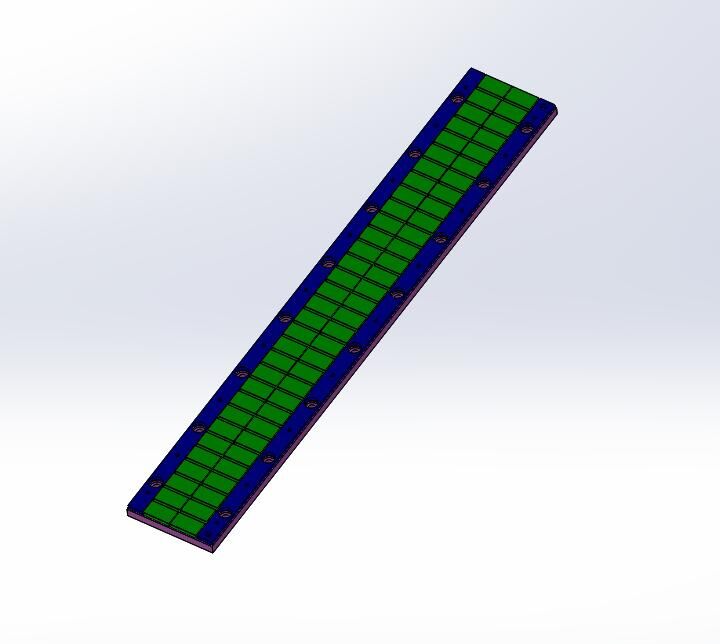

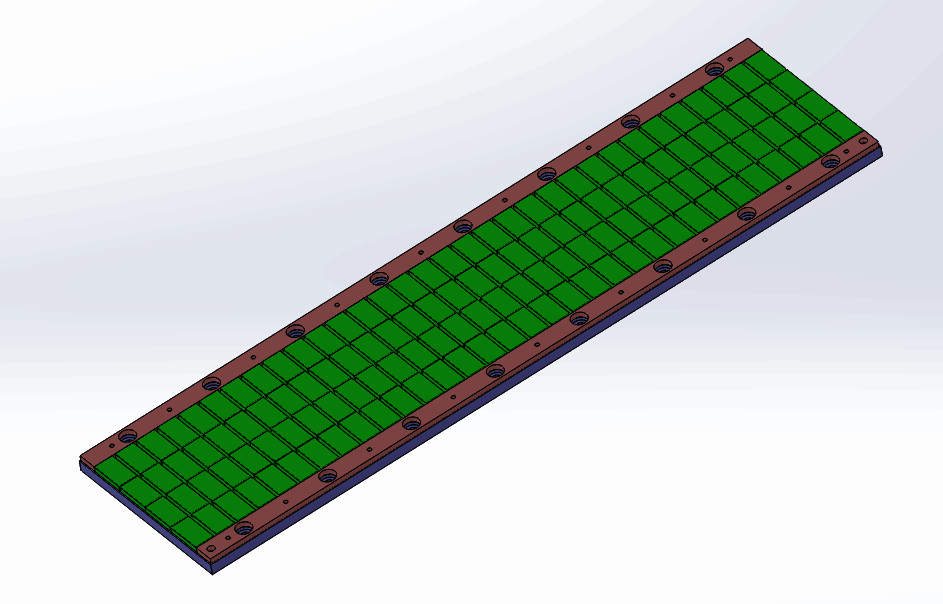

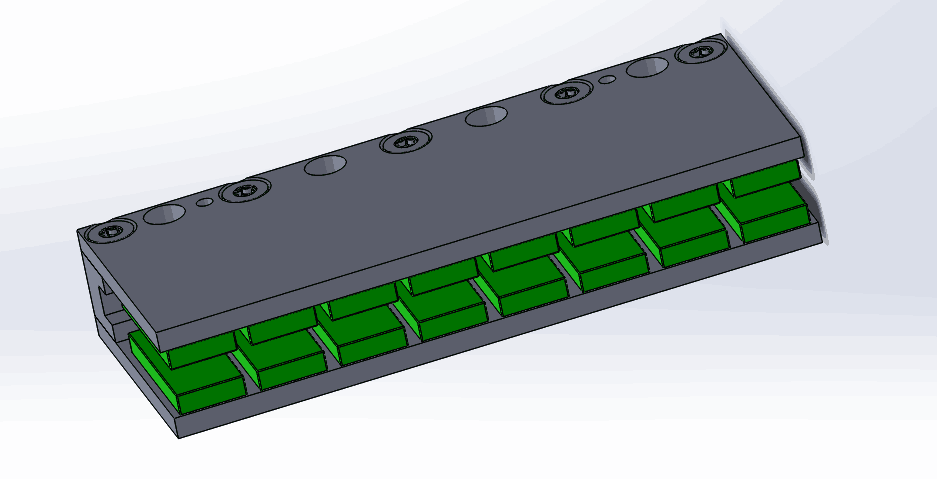

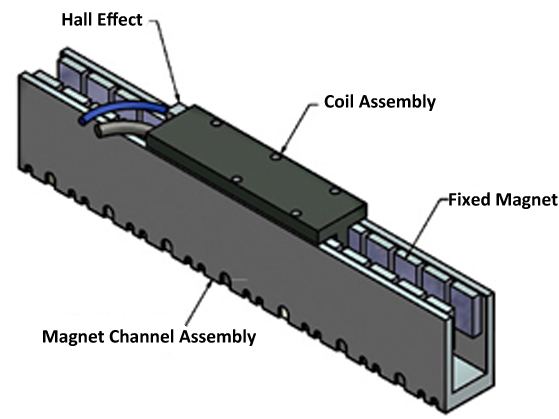

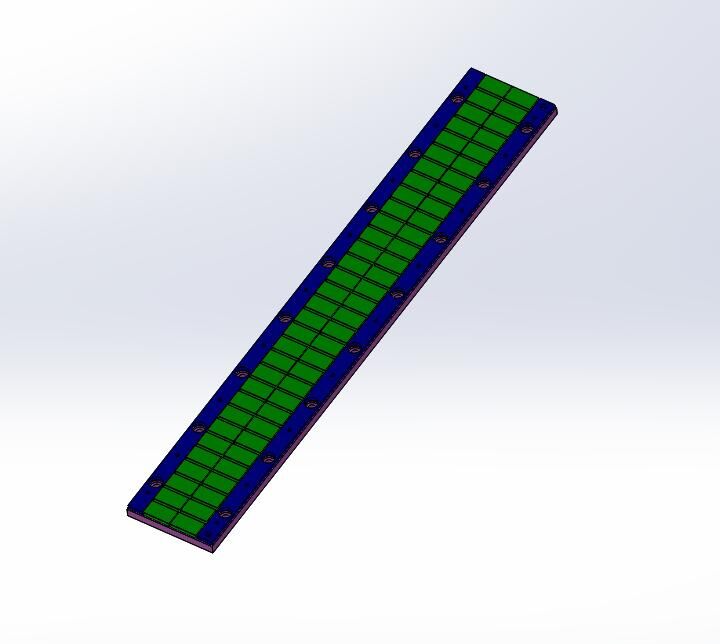

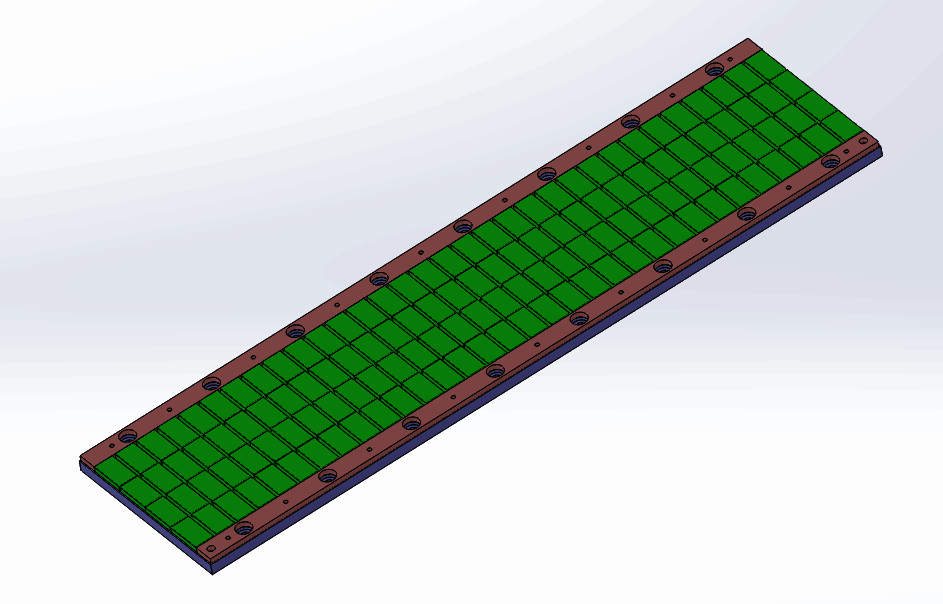

Magnetic Stator of Linear Motor

-

Magnet

is also widely usd in the stator of motors, like linear

motor and voice coil motor(VCM). Our design and assembly

technologies can fit to customers' intergration system,

providing stable and homogeneous magnetic flux

-

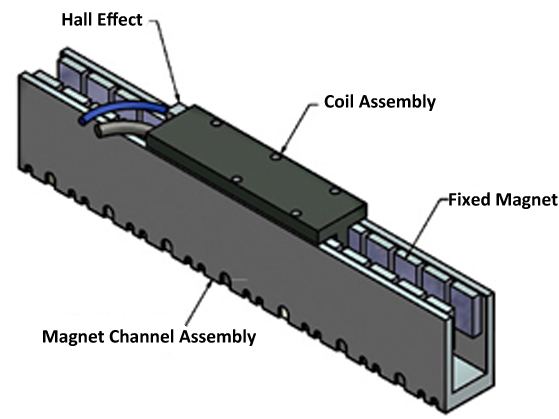

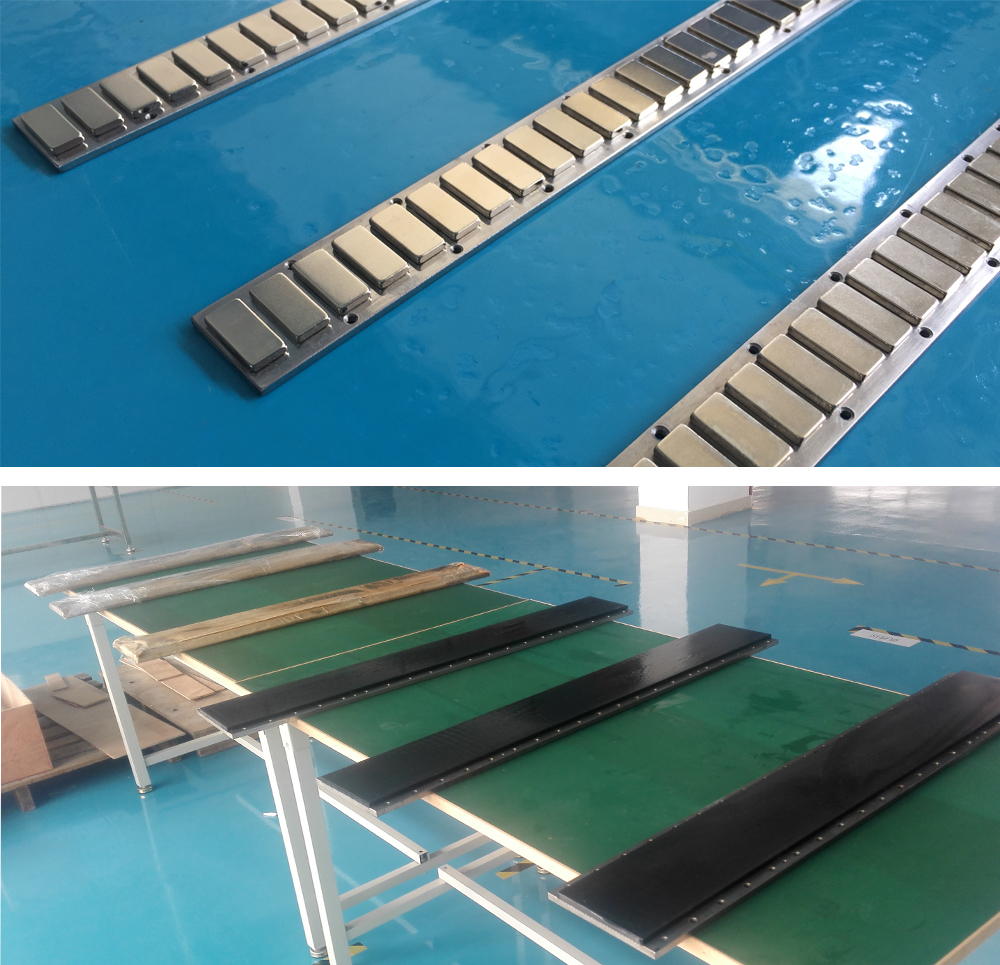

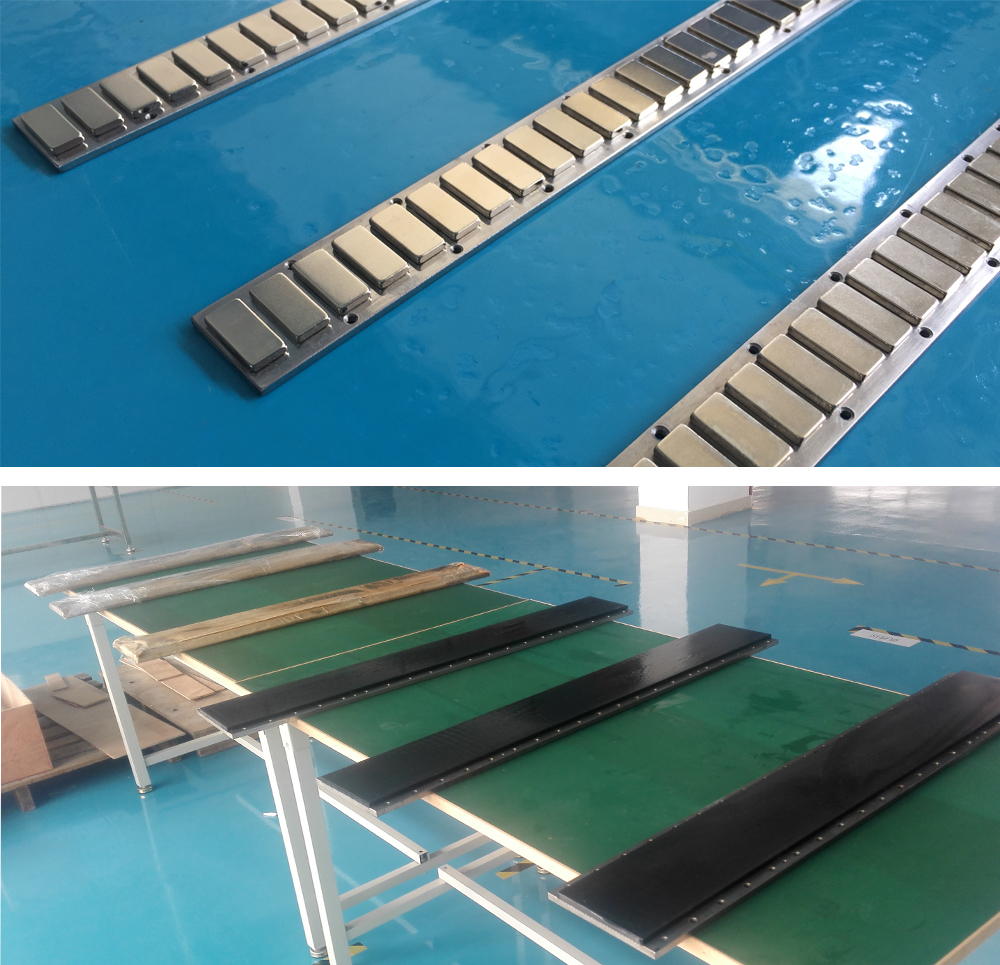

There are

mang hiden technologies in the stator assembly of

linear motor. With similar cost, our assembly experience and

documented technology specification will make high

reliability happen, flat and shining appereance,

perfect gluing effect without overflow, even flux

distribution,etc

-

|

|

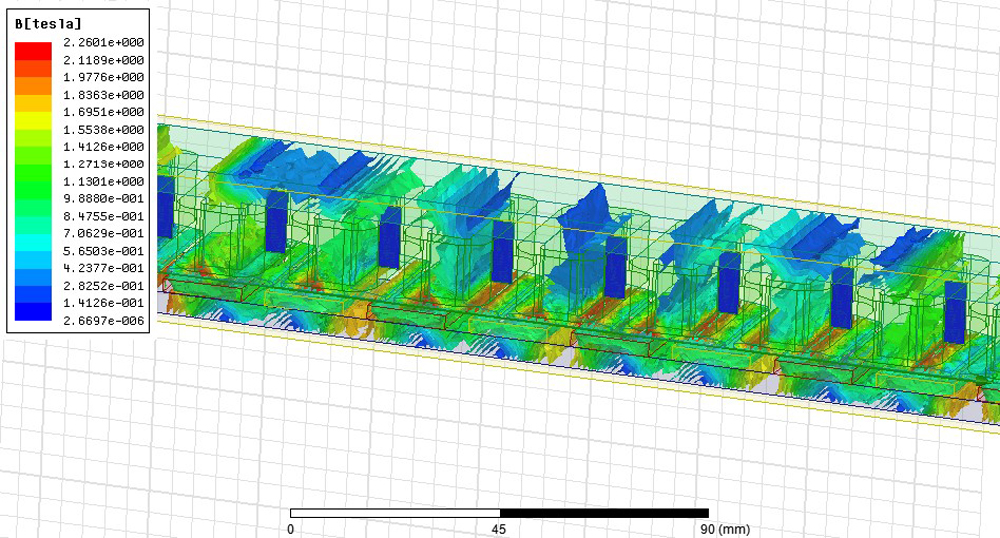

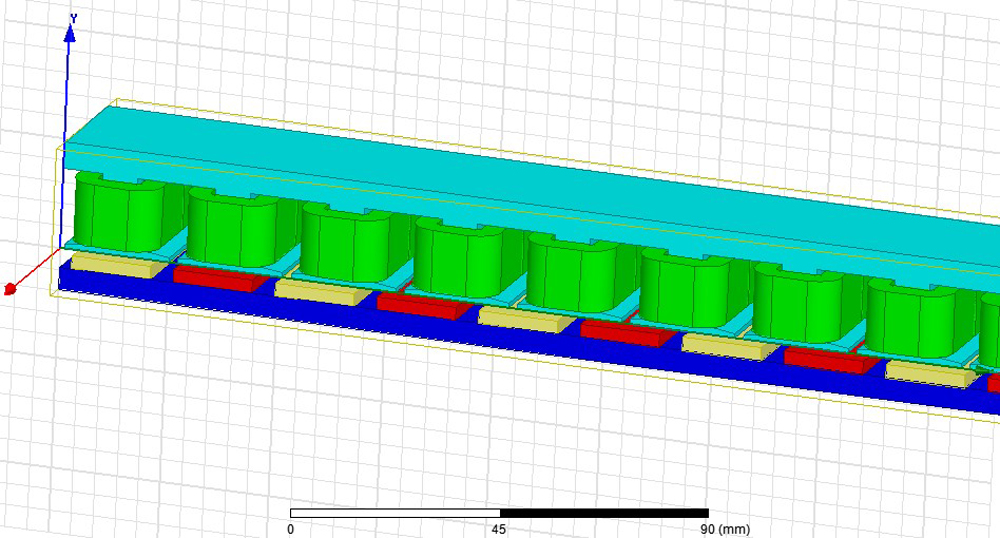

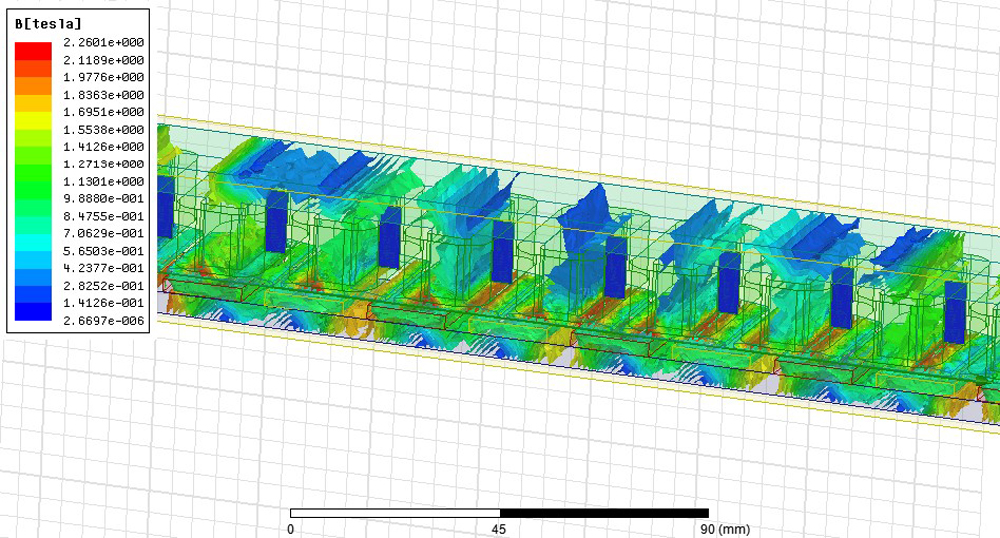

Magnetic

Flux Analysis

The factors

that may determine the efficiency and cost of Linear Motor

1. Magnet

-

N, M, H, SH, EH, AH series NdFeB magnet, AH has the highest

coercivity(Hcj) and working temperature, which is determined by

element Dy. The price of Dy is 4 times of Nd, so unless necessary,

please use magnets as low coercivity as possible(like N or H or SH)

-

Price among N, M, H is only 3%, while 10%~15% between SH and H. Thus

if the magnet is chose to be over SH grade, it would be very

expensive

-

The thickness of the rectangular magnet is better to be bigger than

1mm, otherwise the non-conforming rate is high.

-

Usually ∮0.1 for L and W, ∮0.05 for Thickness

-

Surface treatment: price of NiCuNi is 1.5 times as Zn, while

NiCuNi+epoxy is 2 times as NiCuNi

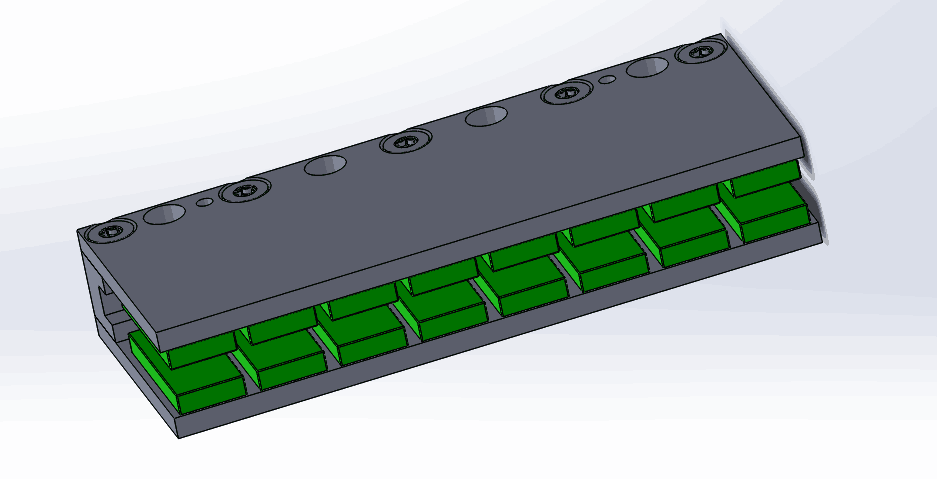

2. Steel Part

-

Itˇs often to buy steel plate in the market of 1, 2, 3, 4 5, 6, 8,

12, 15mm, so please try to make your design closer to those, for

instance, the thickness 8.2mm is much more expensive than 7.8mm.

since to machining 8.2mm ,we have to use 12mm thickness plate, but

for 7.8mm, 8mm plate is far enough

-

Roughness: normally RA6.3 for the gluing surface and RA3.2 for

others. If itˇs required to reach 1.6, we have to grind the surface,

which means higher cost

-

Please try to avoid the tolerance which is stricter than ∮0.01mm

-

Surface treatment: Oxidation(USD1~1.5/kg), Zn(USD1.5~2/kg),

NiCuNi(USD3~4/kg), NiCuNi+epoxy(USD4~6/kg)

-

Usually 1.0114(German)/Q235(China)/A283A(US)

3. Assembly:

|

Glue Type |

Thickness |

Usage Rate |

Efficiency |

cost |

price of Glue |

Application

Description |

|

mm |

% |

pcs/min |

USD/pcs |

USD/L |

|

anaerobic |

0.02~0.05 |

80 |

3 |

0.01548 |

200 |

Under 80C,

medium environment |

|

2-component |

0.1~0.2 |

30~50 |

1 |

0.04839 |

100 |

Under 120C,

acid and alkali |

|

1-component |

0.1~0.2 |

50 |

0.3~0.5 |

0.13548 |

200 |

Under 180C,

acid and alkali |

An example

here:

-

Magnet: 48H

-

Tolerance of magnet, L∮0.1

x W∮0.1

x T∮0.05

-

Material of steel part: Q235, 5mm thickness

-

Plating: NiCuNi for both magnet and steel part

Type

1: USD200/meter

Type 2:

USD300/meter

Type

3: USD420/meter

|